Information and Control System Business

We contribute to the sustainable development of society and industry with the latest digital technology

Information and Control System Business

In the Information and Control System Business, we provide systems that support social infrastructure that is indispensable for a comfortable living environment, such as energy-related facilities and railways. By planning and implementing optimal control methods through modeling and simulation of monitoring and control objects, we improve the quality, utilization rate, and safety of systems and contribute to the realization of a sustainable society.

In addition, we support the transformation of factories into smart factories through the advanced use of the latest digital technologies and data such as AI and robots. We are working to solve problems such as labor shortages and human resource development in the manufacturing industry.

In addition, in the construction and introduction of business systems to companies, we support the construction of automation and efficiency infrastructure and the promotion of DX with business analysis and proposals that align closely to customer needs so that we can flexibly respond to changes in the business environment such as revisions to legislation.

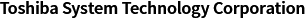

Smart Factory Robotics

“Smart factory” is a concept that refers to an advanced production plant that makes full use of cutting-edge digital technologies.

By collecting various data in the factory through sensing technology, and by using technology such as AI analysis and robotics, companies can gain benefits such as optimizing plant operation and management and reducing costs.

In addition, companies can expect site improvements such as passing on the skills of experienced workers, preventing industrial accidents, and reducing environmental impact.

Business Overview

Current situation analysis

Understand the current situation and issues of the factory, and set goals and policies to become a smart factory.

Design and construction

We build the platform for collecting and accumulating various types of data in the factory so that companies can grasp the operational status of equipment and the stock of materials in real time. In addition, we introduce automation technologies such as AI data analysis and robots.

Operations and improvement

We analyze and visualize the data in the factory to optimize operation and management. We also feed back data to drive factory improvements and innovation.

System Examples

- EQSURV Series

- Appearance inspection AI solution

- Remote vision system

Business System Solutions

Business system solutions support process improvement and DX conversion in companies.

Business systems, sometimes referred to as enterprise systems, play an important part in the business of a company.

Generally, they refer to systems that streamline and automate in-house operations such as production management, sales management, inventory management, and attendance management.

Based on our track record of developing a wide range of business systems within and outside the Toshiba Group, we make full use of our experience and technical capabilities to achieve the best system proposal and construction.

Business Overview

Current situation analysis (interviews/mockup)

By grasping customer issues, interviewing, and creating mockups, we turn customer requests into real solutions that are close to the customer’s original image.

Design, construction, testing

Based on the mockup, we incorporate the requirements into the design document, and select the optimal development method (scratch/low code development/tools, etc.) to build the business system.

Our automated testing also delivers fast, efficient testing and high-quality systems in a short period of time.

Improvement and maintenance

We prepare a maintenance support menu tailored to the needs of the customer to support operations and solve problems.

System Examples

- Group enterprise systems

- Project management systems

- Electronic approval (workflow) systems

- Document management systems

- Internal systems (project management, business improvement, innovation systems)

Railway Systems

Railway systems include areas such as “rolling stock systems”, “power systems”, and “education systems”. Together with the Toshiba Group, we continuously innovate technologies to improve the safety, efficiency, and comfort of railways, contribute to the development of the railway industry, improve possibilities, and meet the needs of society.

Business Overview

Railway rolling stock information systems

Railway rolling stock information systems manage the operation status and failure information of rolling stock. They improve the safety, efficiency and convenience of railways and provide useful features for railway companies and passengers.

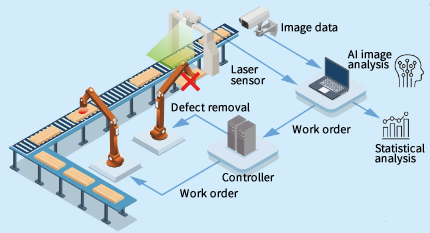

Regenerative power storage systems

With a regenerative power storage system, batteries are installed in the ground equipment which store power from the regenerative brakes and overhead wires, and in the event of a large-scale power outage due to an earthquake or the like, the train can drive by itself to the nearest station using the power from the batteries to ensure the safety and rapid evacuation of passengers.

Railway education systems

Railway education systems are used to teach personnel skills and knowledge related to topics such as railway operation and maintenance. There are crew support systems that simulate faults on a simulation screen of the driver’s seat, allowing simulated experience training, and VR training systems that create a VR version of the train’s cabin for highly realistic driving training.

System Examples

- Railway rolling stock information systems

- Railway rolling stock security camera systems

- Regenerative power storage systems for railways

- Education and training systems for railways